Process monitoring

Real-time monitoring of the process, quality, and tooling.

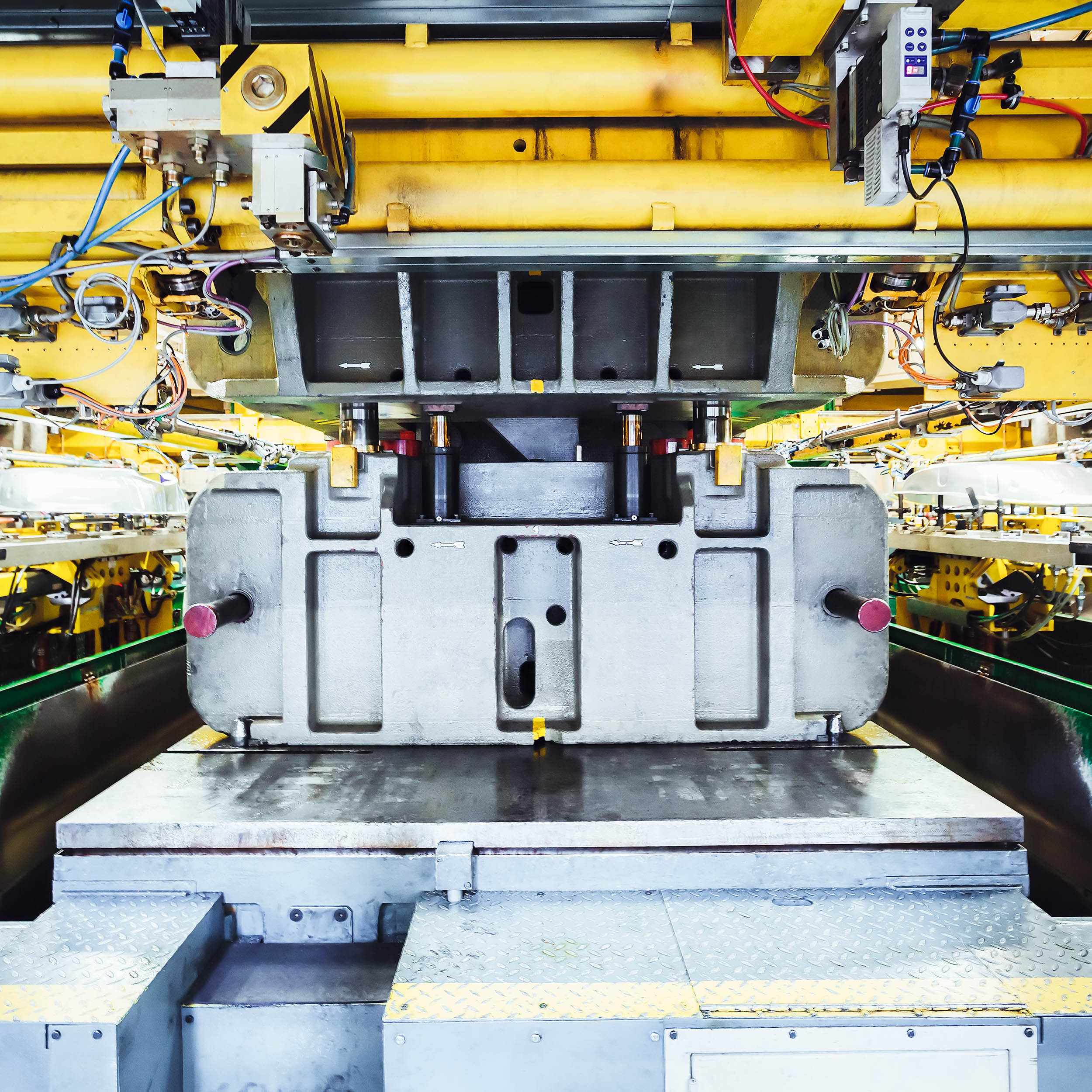

Bulk forming

Ensuring consistent output and eliminating tool crashes are key advantages of process monitoring in bulk forming. The system is applicable to both single-operation and progressive presses.

In progressive presses, monitoring is ensured even during the start-up and run-down of production, as the 4dot system works with boundary conditions. Each operation has its own set of limits, allowing for extremely narrow tolerances and maximum quality.

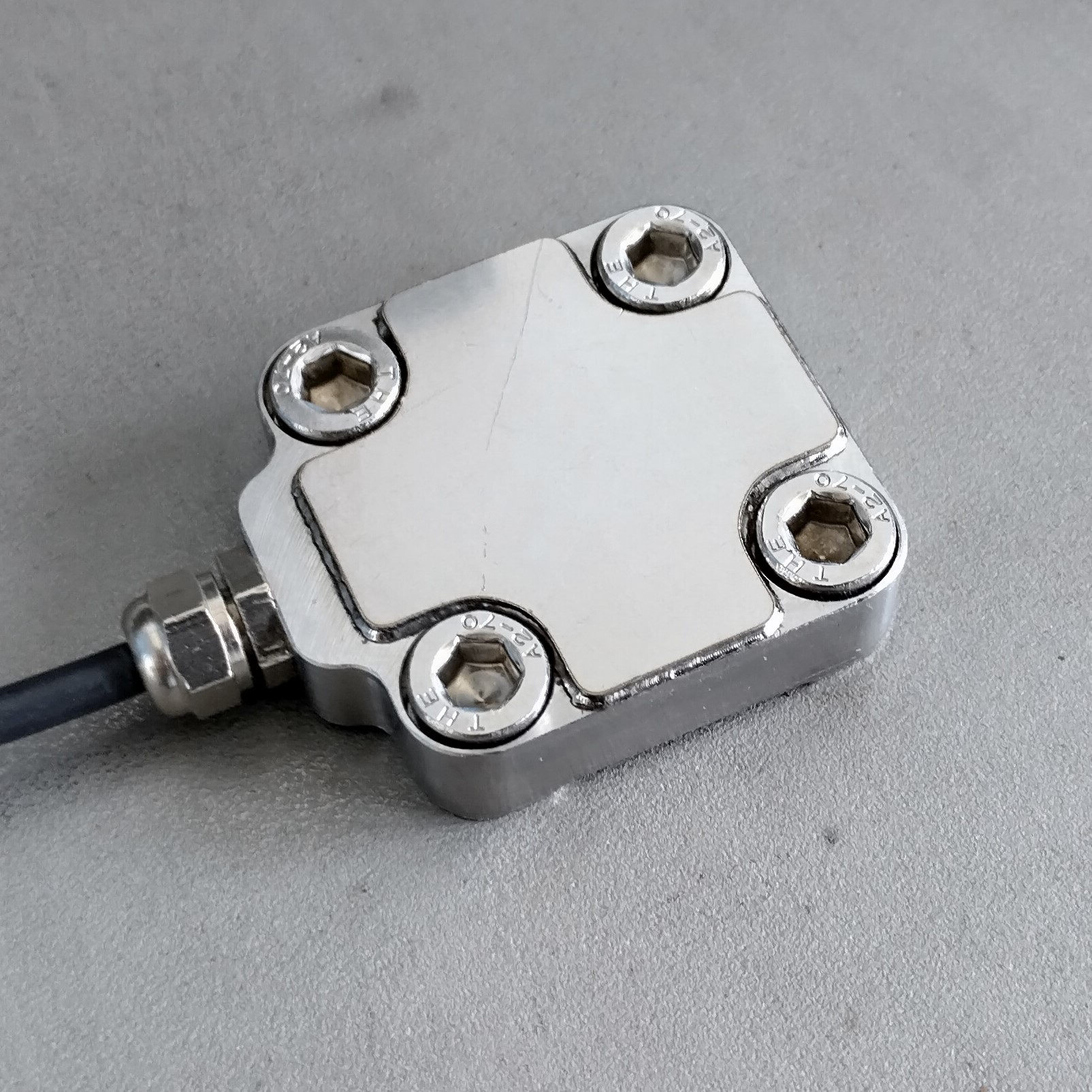

To monitor and control forming force, the Deformation Module is used. It tracks force progression and protects the machine from overload. The Energy Module monitors tool condition by detecting wear, tool damage, and process faults—even in the forming of small components.

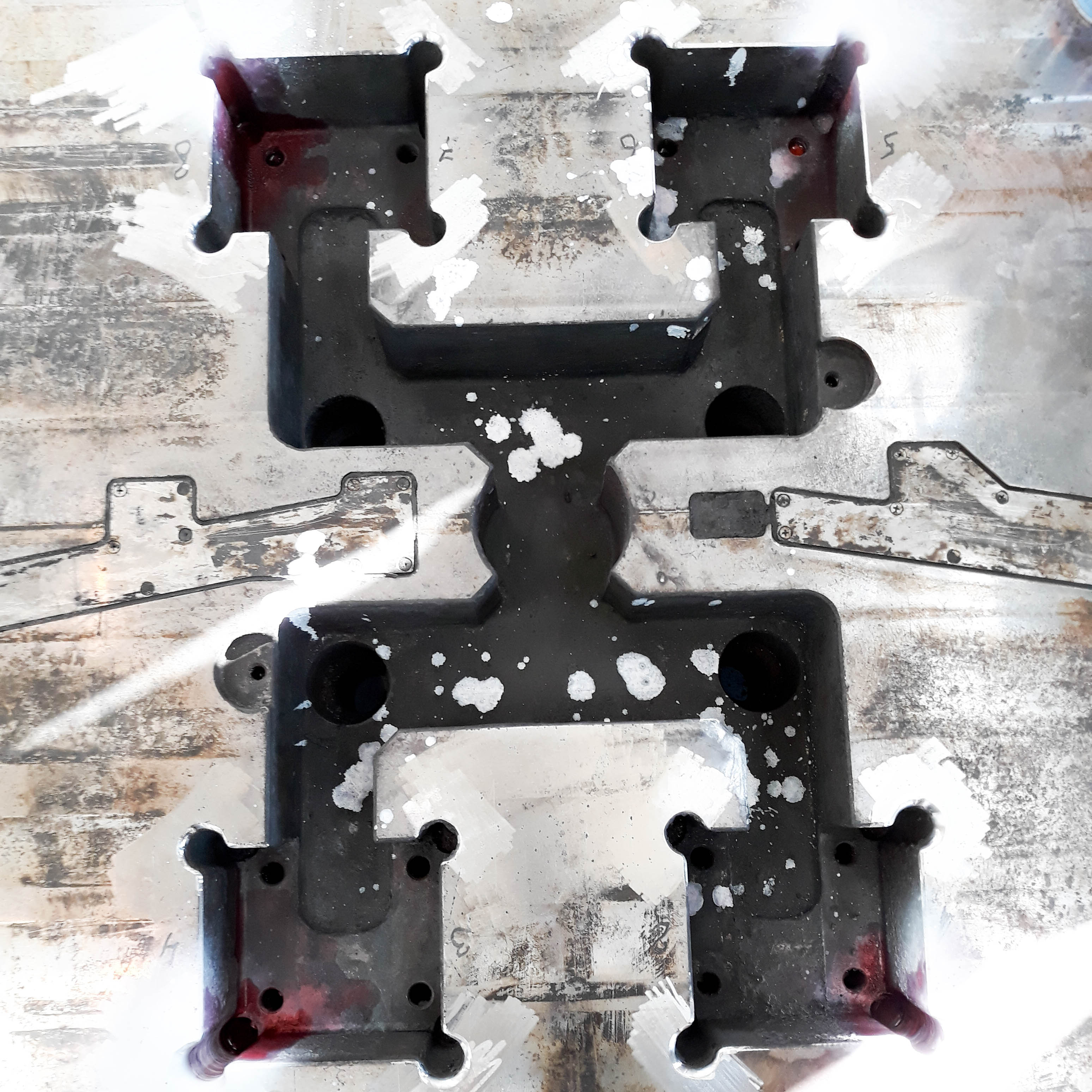

Sheet metal forming

Tool protection during pressing is ensured by maintaining high precision of individual sheet forming parameters. The Energy Module enables monitoring of lubrication, smooth operation, and detection of potential tool galling.

The Deformation Module tracks both pressing force and the force during tool opening, reliably detecting changes in tool condition regardless of the pressing itself.

The Motion Module evaluates alignment and flatness of the working tool parts during operation, allowing early detection of deviations from the desired state.

High motion precision and good tool condition are essential for achieving high production quality.

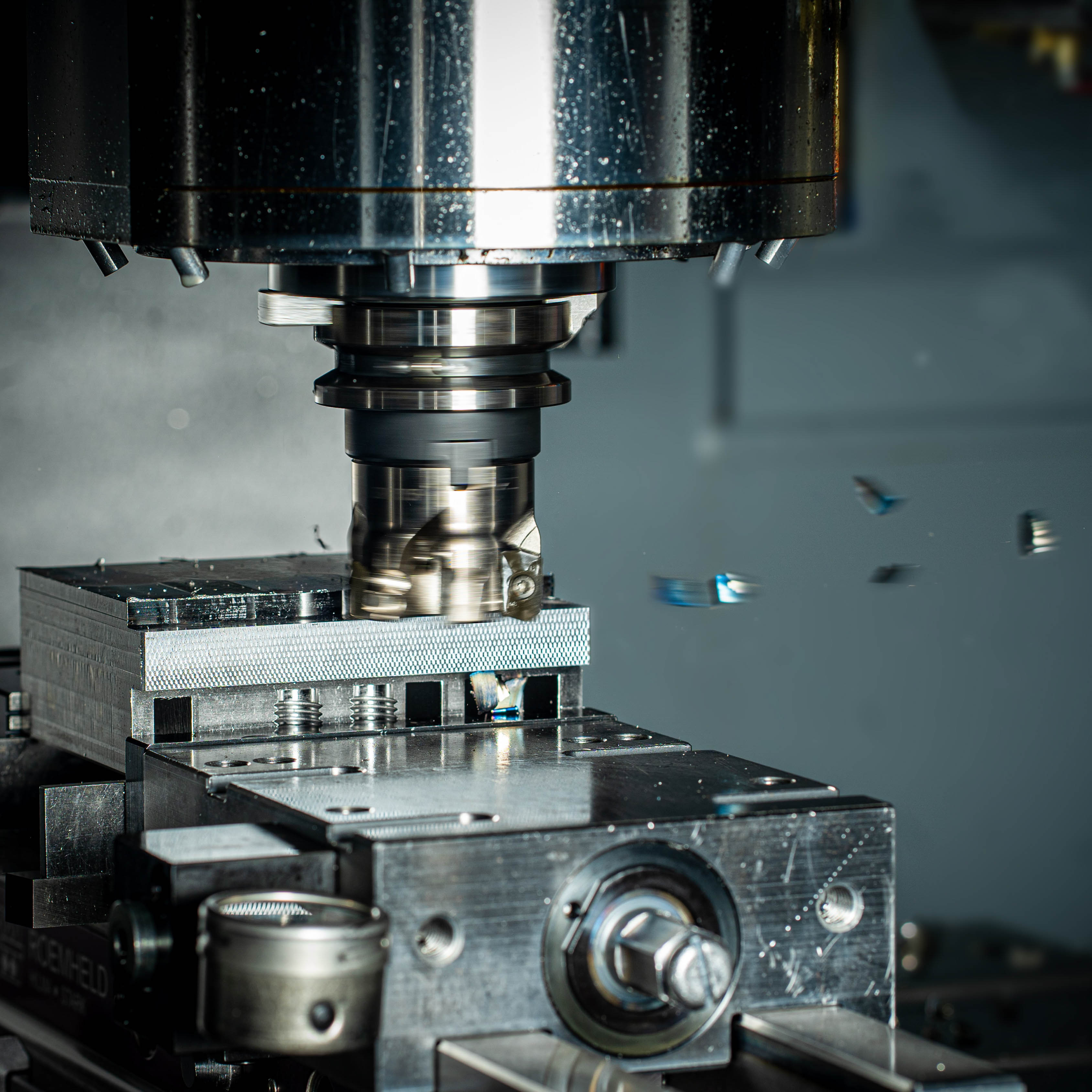

Machining

Process monitoring by 4dot enables tool replacement before quality deteriorates, stops machining in case of cutting insert breakage, detects collisions, and monitors tool–workpiece contact for adaptive machining control.

The core of the technology is the Energy Module, which detects insert breakage, wear, contact with the material, and potential collisions. For force evaluation and deeper analysis of the machining process, the Deformation Module is also used.

Monitoring can be applied to both turning and rotary tool machining.

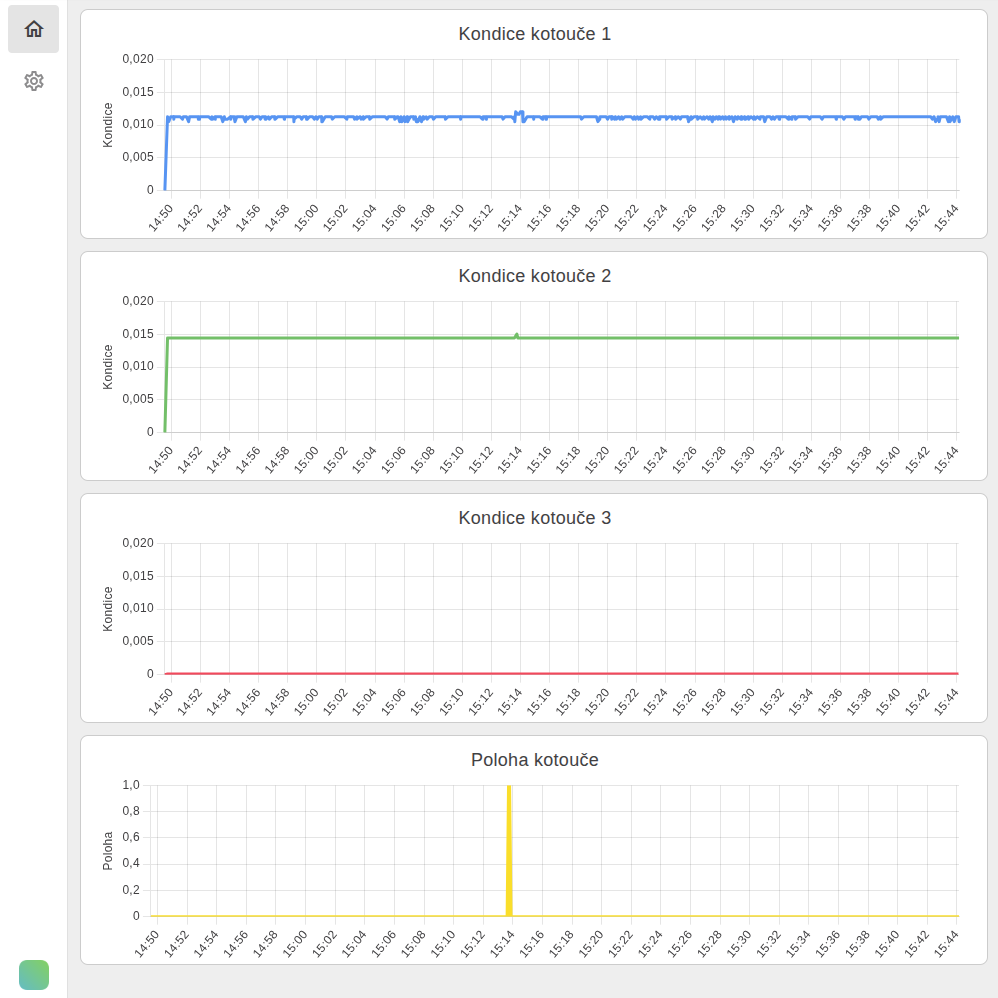

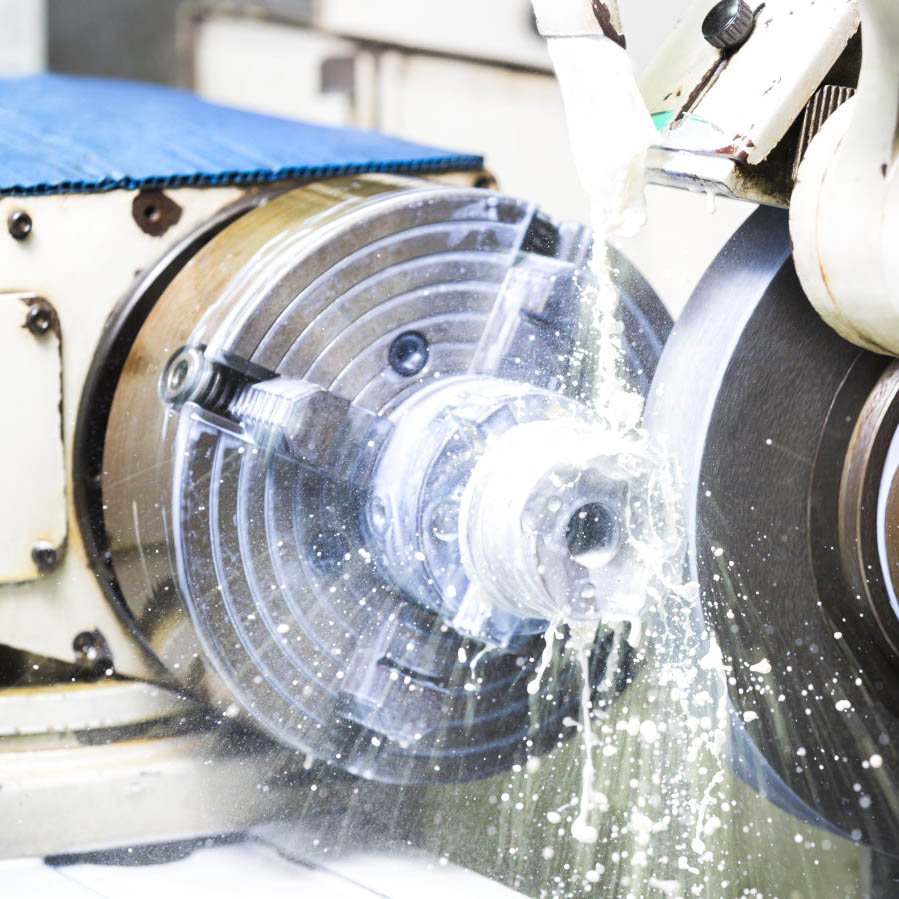

Grinding

Real-time monitoring of workpiece and tool geometry, as well as surface integrity assessment, is made possible by 4dot process monitoring, which provides information for adaptive control of the grinding process.

The system is based on the Energy Module, which continuously monitors material removal intensity during grinding. In combination with patented MUSA analyses, it allows evaluation of current workpiece geometry and abrasive condition.

When combined with tool displacement data, it is also possible to precisely monitor the amount of material removed—crucial for ensuring surface integrity in stressed components such as rolling bearings.