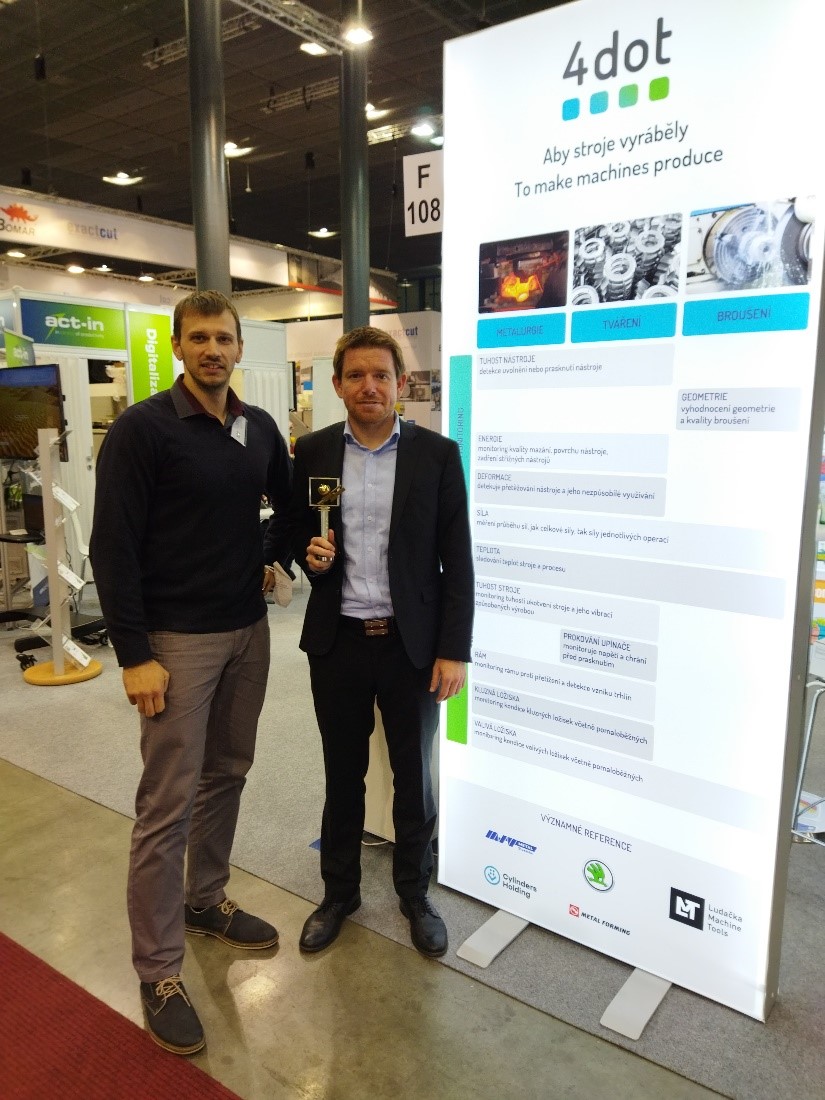

The 4dot SM rework sensor, which brings savings in production, was awarded the Gold Medal at MSV Brno. 4dot thanks its partners and remembers its values.

"When we deployed our first rework sensor as part of our technology monitoring, we used commonly available technology and the sensor lasted a few hours in the forge. After several years of development, we have in our hands a durable, accurate 4dot SM overmold sensor with easy installation that can be deployed even in heavy industry. We believe this sensor is the way to go for our technology monitoring in foreign markets.

I want to remember the founder of Zbrojovka Brno. We have built on the values they instilled in us and translated them for the needs of the 21st century. Senzor and the award we received are the result of our efforts to be independent, to have a final product, our own sales, and to show the way how the Czech economy can be built.

I want to thank all the members of our team. Equally important were and are our customers who have walked this path with us. I thank them from knowledge, through technologists, maintenance workers to machine operators. Without those who have supported us, this product would not have come into existence," says 4dot CEO Ing. Jan Otoupalík on the occasion of the award of the 4dot SM Transformation Sensor with the Gold Medal at MSV Brno 2021.

The 4dot SM deformation sensor is a key component of the Deformation, Force, Clamp Interlace and Frame modules. Due to the sensor's high sensitivity, durability and ease of installation, the modules can deliver reduced material consumption, increased quality, extended tool life and extended service intervals. The sensor and most of the modules are unique in the market and have no direct competition, they are also patent protected. Each module has specific benefits for the customer, the system is built from individual modules according to the customer's needs. Technology monitoring 4dot has already been deployed by companies such as Škoda Auto, Metaldyne Oslavany or Vítkovice Cylinder.

Our technology is divided into Technology Monitoring and Predictive Maintenance. Technological monitoring monitors the link between the tool and the future product, allowing insight into places where a sensor or camera cannot be placed. Predictive Maintenance uses the same sensors to detect incipient failures in mechanical parts so that maintenance can intervene in a timely manner at minimal cost.

The technology monitoring modules using the award-winning 4dot SM Transformation Sensor are Deformation and Strength. The Deformation module is a tool for reducing scrap, reducing material consumption, extending tool life and quality control. According to our customers, for example, tool savings of up to 15% are achieved, says 4dot CEO Ing. Jan Otoupalík. The deformation module enables the detection of small deviations in tool loading, detecting an incipient problem and reacting to it immediately. The Deformation Module is suitable for all types of multi-operation tools on a single fixture. The Force module has the same benefits as the Deformation module, but is designed for single and multi-operation single clamp presses. In addition to tool protection and quality control, the Force module also protects the machine frame and works with precision force.

The predictive maintenance modules using the award-winning 4dot SM Overformation Sensor are Clamp Forging and Frame. The Clamp Forging module is a simplified Deformation module that mainly protects the clamp from breaking. This prevents long unplanned production downtime and costs in the millions. The Frame module guards the press against frame breakage and reduces repeated frame overloading at critical points. Furthermore, the Frame module allows the detection of cracks and thus their repair before the entire frame breaks. The cost of a frame break is in the tens to hundreds of millions of crowns.

Our company presented the 4dot SM Transformation Sensor at MSV Brno on Monday 8 November 2021. Thanks to its combination of sensitivity, design and durability, the sensor has no alternative on the market. Our developers have achieved sensitivity comparable to piezoelectric sensors, enhanced by the ability to measure even constant loads, which a piezoelectric sensor does not allow. The unique design allows for simple manufacturing and easy assembly. The 4dot SM strain sensor has already received a patent in the Czech Republic, and we are pursuing patents in the EU and overseas.